Straw Dryer

Introduction

The straw dryer is suitable for drying barley straw, oat straw, wheat straw, rye straw, sorghum straw, and corn straw. Based on the characteristics, yield, application requirements, cost control, and ease of operation of each type of straw, the drying process technology is optimized, which saves energy and drying costs by 30-50% compared to ordinary dryers.

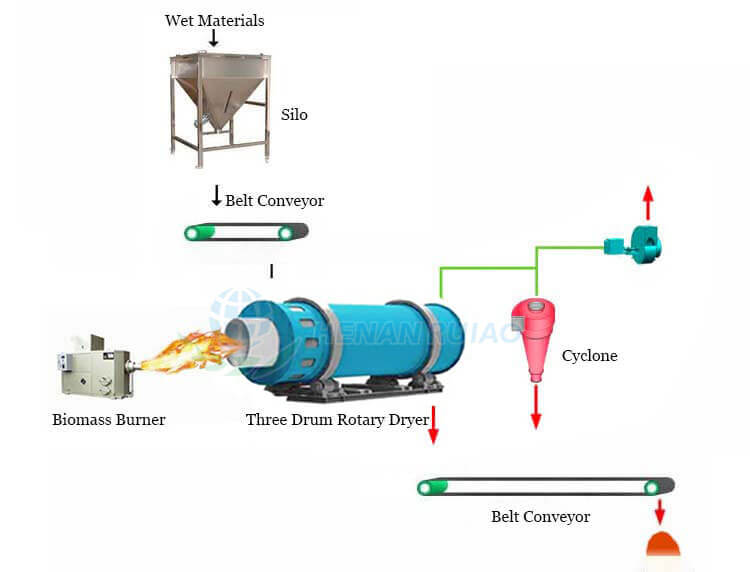

Working Principle

The wet material enters the straw dryer from the feeding bin through the belt conveyor. Inner the drum, the material is fully mixed with hot air for wet heat exchange, High temperature air transfers heat to the wet material, causing the temperature of the wet material to rise. The moisture of the wet material evaporates and the water evaporated is discharged into hot air to achieve drying of wet materials.

Advantages

1. The main structure of the dryer is simple, with few faults, low maintenance costs, large processing capacity, and can ensure long-term continuous operation.

2. The full drying system adopts electrical centralized control, with automatic adjustment of hot air temperature, which is convenient for operation.

3. A specially designed strong disperser is used inner the drum to solve the problems of adhesion and agglomeration of viscous materials during the drying process, improving the drying effect.

4. Adopting a unique sealing device and matching it with a well functioning insulation system to reduce the energy consumption of the drying system.

5. The overall system has good sealing performance and is equipped with a complete dust removal device, with no dust leakage and a good working environment.

Technical Parameters

Model | RASG2010-3 | RASG2209-3 | RASG2609-3 | RASG3009-3 |

Capacity | 1-2t/h | 1-2t/h | 2-3t/h | 4-6t/h |

Input moisture | 35-60% | |||

Output moisture | 12-15% | |||

Drying temperature | 450℃ | |||

Floor space | 10m×20m | 10m×20m | 15m×30m | 15m×40m |

Send a Message

Get In Touch!

Address

No.11 Changchun Road, High-Tech Development Zone, Zhengzhou, Henan, China

- 19900970386