Spent Grain Dryer

Introduction

Wet spent grain is easy to deteriorate and pollute the environment during transportation and storage. The spent grain dryer manufactured by our company is applicable to the drying line of brewer’s grain, corn spent grain, buckwheat spent grain,etc.

Our spent grain dryer can firstly pre-dehydrate the wet distiller’s grain with a moisture content of about 85%, and then dry it into the dried material with a moisture content of about 10%. And this spent grains dryer uses secondary dedusting and purification equipment, the drying process is clean and environmentally friendly.

Working Principle

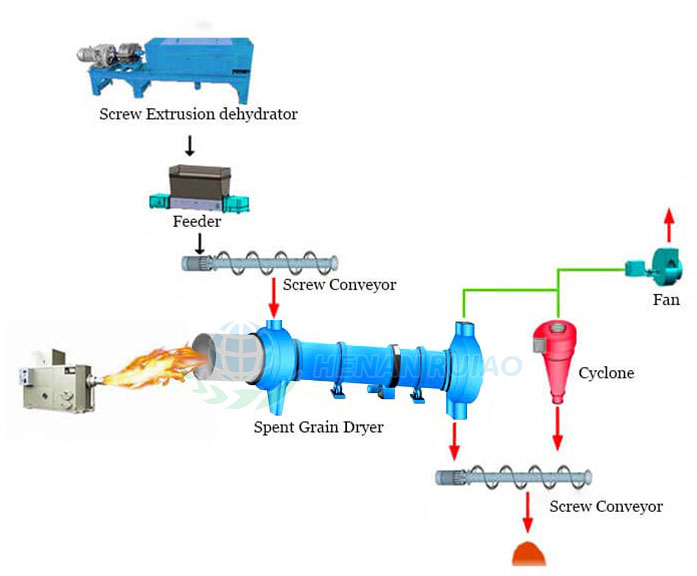

The spent grain dryer mainly consists of heat source, feeder, dryer host, induced draft fan, discharge device, and power distribution cabinet. After dehydration, the wet distiller’s grains enter the dryer and are evenly dispersed in the dryer under the rotation of the evenly distributed boards in the drum, fully in contact with hot air. During the drying process, under the action of the inclined lifting plate and hot air, the spent grain is discharged to the unloader at the other end of the dryer.

Advantages

1. The spent grain dryer has a high degree of mechanization and a large processing capacity, achieving 24-hour continuous operation.

2. The main components of the dryer line are made of high-end materials, with reliable quality and a service life 3-5 times that of ordinary dryers.

3. Installing a combination type lifting device with high thermal efficiency and good drying effect.

4. The dust removal device installed on the dryer can completely avoid dust pollution during operation, achieving green and environmentally friendly production requirements.

5. The thermal energy loss during the equipment drying process is very low, which saves energy and reduces consumption, and has low production costs.

6. Using variable frequency speed regulation to control the flow rate of distiller’s grains, the final moisture index can be easily adjusted according to user needs.

Technical Parameters

Model | RASG2010-3 | RASG2209-3 | RASG2609-3 | RASG3009-3 |

Capacity | 1-2t/h | 1-2t/h | 2-3t/h | 4-6t/h |

Input moisture | 35-60% | |||

Output moisture | 12-15% | |||

Drying temperature | 450℃ | |||

Floor space | 10m×20m | 10m×20m | 15m×30m | 15m×40m |

Send a Message

Get In Touch!

Address

No.11 Changchun Road, High-Tech Development Zone, Zhengzhou, Henan, China

- 19900970386