Sludge Dryer

Sludge Rotary Dryer Introduction

Sludge has high moisture content and high viscosity. It is easy to stick to the wall, agglomerate, and block during the traditional drying process, resulting in high energy consumption.

Ruiao New Energy has developed a sludge rotary dryer based on many years of experience in comprehensive moisture treatment of high-humidity materials. It is equipped with special dehydration, temperature adjustment, material lifting, material guiding, dispersing and other devices, which effectively avoids sticking wall, clogging, etc. The sludge dryer can dehydrate and dry all kinds of sludge with a moisture content of up to about 90%, and the moisture content of the finished product can be dried to 12%.

Sludge rotary dryer can be used to dry chemical sludge, papermaking sludge, textile sludge, painting sludge, leather sludge, heavy metal sludge, municipal sludge and drain sludge, etc.

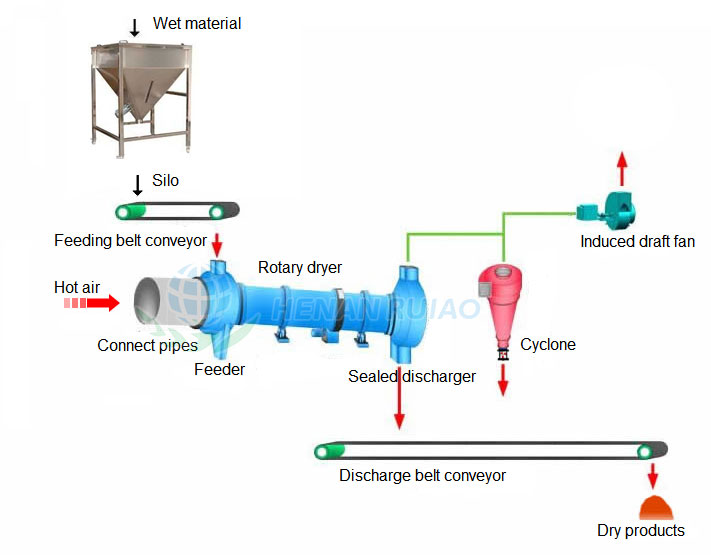

Sludge Rotary Dryer System

The sludge dryer is mainly composed of an induced draft fan, a dispersing device, a belt loading machine, a feeder, a rotary drum, a heat source, a belt discharging machine, an unloader and a power distribution cabinet. Therefore, the working area of the single-channel sludge dryer consists of the discharging area, the inclined lifting plate area, the cleaning area, and the guide area.

Sludge Rotary Dryer Advantages

The rotary drum sludge dryer boasts several key features that make it a preferred choice for efficiently drying sludge in various wastewater treatment applications.

1. Continuous Operation

The rotary drum design allows for continuous processing, ensuring a steady and uninterrupted drying operation. This is particularly beneficial for wastewater treatment plants with a continuous inflow of sludge.

2. Uniform Drying

The rotating drum facilitates uniform exposure of sludge to heat, ensuring consistent and thorough drying throughout the material. This prevents uneven drying or the formation of clumps, resulting in a high-quality, homogenous dried sludge.

3. Adjustable Parameters

Operators can control various parameters, including temperature, residence time, and air flow, to optimize the drying process for different types of sludge. This flexibility enhances the adaptability of the dryer to various sludge characteristics.

4. Reduced Volume and Increased Solids Concentration

The drying process significantly reduces the volume of sludge by removing water content, resulting in a more concentrated and manageable end product. This feature makes transportation, handling, and disposal of the dried sludge more cost-effective.

Sludge Rotary Dryer Technical Parameters

| Model | Capacity(T/D) | Input Moisture(%) | Output Moisture(%) | Power(kw) | Floor Space(㎡) |

| RAMG1918 | 300±10 | 25±5 | ≤5 | 109 | 7m×25m |

| RAMG2218 | 500±10 | 25±5 | ≤5 | 128 | 8m×30m |

| RAMG2520 | 700±12 | 25±5 | ≤5 | 240 | 8m×30m |

| RAMG2822 | 1000±15 | 25±5 | ≤5 | 400 | 8m×40m |

| RAMG3024 | 1200±20 | 25±5 | ≤5 | 480 | 12m×50m |

| RAMG3428 | 1500±30 | 25±5 | ≤5 | 600 | 12m×60m |

| RAMG3830 | 1800±30 | 25±5 | ≤5 | 800 | 16m×70m |

| RAMG4032 | 2000±30 | 25±5 | ≤5 | 1000 | 18m×70m |

| RAMG4238 | 2500±30 | 25±5 | ≤5 | 1200 | 20m×80m |

Send a Message

Get In Touch!

Address

No.11 Changchun Road, High-Tech Development Zone, Zhengzhou, Henan, China

- 19900970386