Ore Dryer

Ore Dryer Introduction

A rotary dryer is an efficient moisture removal machine that lets you dry ores in large quantities. Its high-temperature drying ensures quick evaporation of water content. And its internal design varies from the characteristics of the mineral to be processed. It can be used for copper, iron ore, nickel, zinc ore , gold and silver ore, platinum group metal concentrates, etc. The final moisture content of the dried material can be less then 5% and can be adjustable according to your needs.

Ore Dryer Working Principle

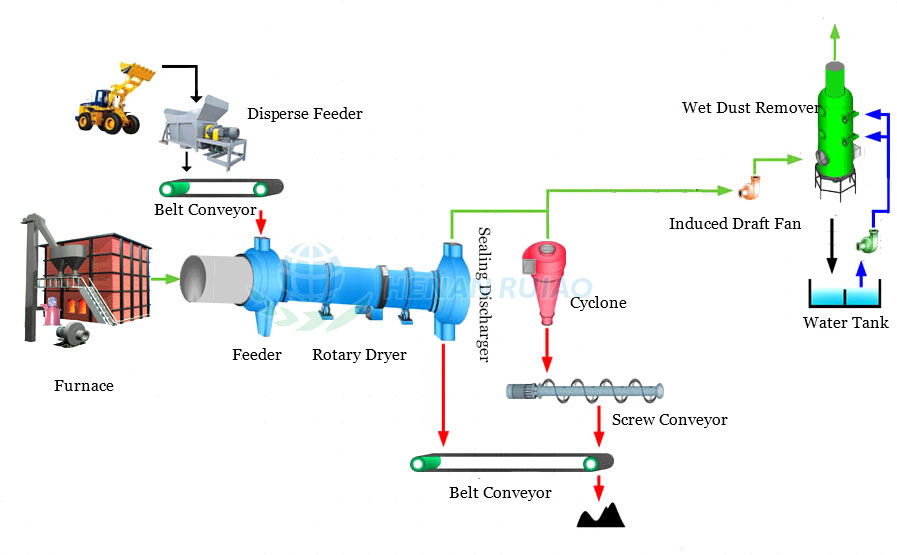

The iron ore dryer is mainly composed of a rotary cylinder, transmission device, reducer, supporting device, sealing device, lifting flights, self-cleaning device, conveying device, etc.

The wet ore to be dried are transported by the feeding hopper and feeding conveyor. The auxiliary blower adds air to the burner and delivers the hot gas into the combustion chamber. The hot air vaporizes the water in the mineral ore.

After passing through the dryer, the dried ore are discharged to the conveyor belt for further sorting and separation. Steam from the process is drawn into cyclones and/or bag dust collector, which are specifically designed to handle fine dust, to remove fine particles from the steam stream. The exhaust gas is finally discharged through the exhaust chimney.

Ore Dryer Advantages

1. Large drying intensity, short drying time and large effective drying area;

2. After drying, the material moisture can reach 0.5-1%, and it is adjustable.

3. The structure is simple, the area is small, and it is easy to construct and maintain;

4. Large processing capacity, thermal efficiency up to 60%;

5. The drum dryer adopts “aligning roller device”, which greatly reduces wear and power loss.

Technical Parameters

Model | Drum diameter | Drum | Capacity | Final Moisture Content (%) | Drum Inclination | Power | Weight |

RAKΦ1.0×10 | Φ1000 | 10000 | 1-4 | ≤5% | 5 | 7.5 | 7.85 |

RAKΦ1.2×12 | Φ1200 | 12000 | 3-7 | ≤5% | 5 | 11 | 13.3 |

RAKΦ1.5×14 | Φ1500 | 14000 | 7-10 | ≤5% | 5 | 15 | 17.9 |

RAKΦ1.6×14 | Φ1600 | 14000 | 8-11 | ≤5% | 5 | 15 | 18.6 |

RAKΦ1.8×14 | Φ1800 | 14000 | 9-13 | ≤5% | 5 | 15 | 20.85 |

RAKΦ2.4×18 | Φ2400 | 18000 | 21-31 | ≤5% | 4 | 30 | 45 |

RAKΦ2.4×22 | Φ2400 | 22000 | 26-38 | ≤5% | 4 | 37 | 58 |

RAKΦ2.6×20 | Φ2600 | 20000 | 28-40 | ≤5% | 4 | 45 | 60.5 |

RAKΦ3.0×25 | Φ3000 | 25000 | 46-64 | ≤5% | 4 | 75 | 96 |

RAKΦ3.2×25 | Φ3200 | 25000 | 60-80 | ≤5% | 4 | 90 | 119 |

Send a Message

Get In Touch!

Address

No.11 Changchun Road, High-Tech Development Zone, Zhengzhou, Henan, China

- 19900970386