Coal Slime Dryer

Introduction

Coal slurry is the waste discharged from coal production by coal enterprises. Due to its high moisture content, high viscosity, high water holding capacity, and low calorific value, it is difficult to achieve industrial application. Developing comprehensive utilization of coal slurry is an important measure and necessary means to build resource-saving and environmentally friendly mining areas.

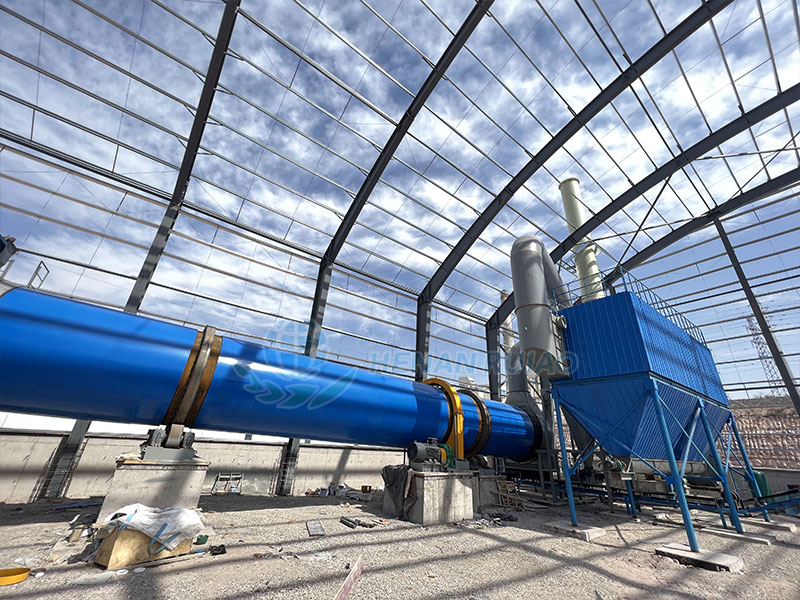

After years of research and public relations, Ruiao New Energy has developed a complete set of environmentally friendly coal slurry drying machine system. This system effectively solves the problem of wall sticking during the coal slurry drying process through different forms of lifting devices, cleaning devices, and crushing devices inside the drum, achieving standardized and improved utilization of coal slurry resources.

Structural Composition

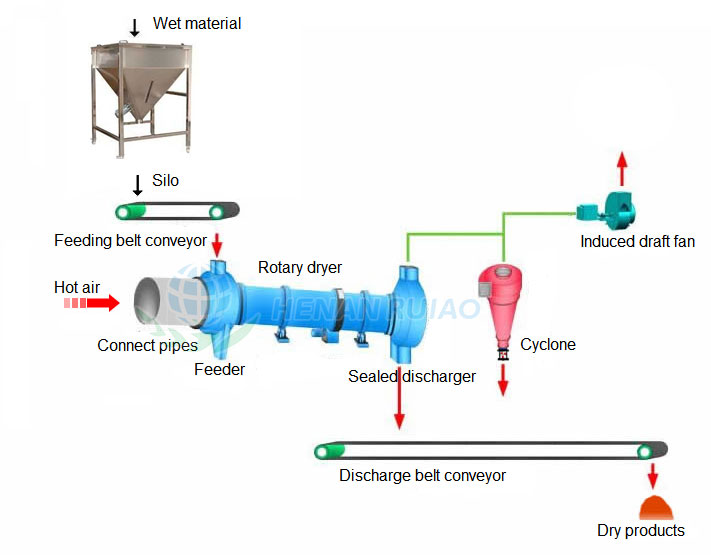

1. Raw material loading system: including a dispersing feeder, a feeding belt conveyor, etc., to ensure uniform and continuous feeding.

2. Combustion heating system: including high-efficiency boiling furnace, automatic chain grate furnace, coal powder injection furnace and other high-efficiency hot air systems, ensuring stable high-temperature thermal medium is provided to the drying system.

3. Drying and dehydration system: Select sealed feeding boxes, spiral thrusters, drum dryers, discharge boxes and other equipment to complete the mass and heat exchange between high moisture materials and high-temperature thermal media.

4. Tail gas circulation system: cyclone dust collector, bag filter, induced draft fan and other equipment are used to preliminarily treat the tail gas and send it to the centralized dust removal system.

5. Power distribution measurement and control system: Select a complete set of power distribution devices, local boxes, temperature control sensors and other electrical equipment to achieve control and monitoring of the drying system.

6. Product conveying system: Use a belt conveyor to transport the dried product to the designated location.

Technological Advantages

1. Specially designed coal slurry dispersion buffer feeding equipment effectively alleviates problems such as uneven, discontinuous, and large instantaneous feeding amount.

2. Continuously improving feeding propulsion equipment, making feeding more uniform and smooth, significantly improving heat resistance and reliability.

3. Flexible and diverse combustion equipment, furnace body and furnace type design, pursuing efficient and energy-saving heat source utilization schemes.

4. Fiberglass and stainless steel materials are used in dust removal systems to solve dust removal technical problems such as wear and corrosion.

5. The successful application of bag filter has opened up new ideas for high-temperature and high humidity tail gas dust removal.

6. Equipped with advanced, reliable and practical power supply and distribution and control systems, greatly improving the automation level of the system.

7. Unique sealing equipment for feeding and discharging ensures high thermal efficiency while achieving flexible transportation of materials.

Technical Parameters

| Model | Capacity(T/D) | Input Moisture(%) | Output Moisture(%) | Power(kw) | Floor Space(㎡) |

| RAMG1918 | 300±10 | 25±5 | 13±2 | 109 | 7m×25m |

| RAMG2218 | 500±10 | 25±5 | 13±2 | 128 | 8m×30m |

| RAMG2520 | 700±12 | 25±5 | 13±2 | 240 | 8m×30m |

| RAMG2822 | 1000±15 | 25±5 | 13±2 | 400 | 8m×40m |

| RAMG3024 | 1200±20 | 25±5 | 13±2 | 480 | 12m×50m |

| RAMG3428 | 1500±30 | 25±5 | 13±2 | 600 | 12m×60m |

| RAMG3830 | 1800±30 | 25±5 | 13±2 | 800 | 16m×70m |

| RAMG4032 | 2000±30 | 25±5 | 13±2 | 1000 | 18m×70m |

| RAMG4238 | 2500±30 | 25±5 | 13±2 | 1200 | 20m×80m |

Send a Message

Get In Touch!

Address

No.11 Changchun Road, High-Tech Development Zone, Zhengzhou, Henan, China

- 19900970386