Clay Dryer

Introduction

The clay dryer is mainly used for the drying of various types of clay mud such as bentonite, kaolin, aluminum, and iron clay. While there are many types of clay, each with wide variation in characteristics, the majority of industrial clay mineral producers have one thing in common: they rely on a drying step to prepare a quality clay product for market. As with many mined materials, drying often contributes to easier handling and lower transportation costs, it plays an especially critical role in allowing producers to engineer industrial clay materials and products with the qualities their market demands. We successfully launched the clay dryer according to this to customer needs, and solves some problems of sticking, crushing.

Advantages

1. The drying intensity is high. Since the material is highly dispersed in the air flow, the entire surface of the particles is actively the effective area for drying, and the drying time is short;

2. The air flow dryer has a simple structure, small footprint, and is easy to build and maintain;

3. Large processing capacity and high thermal efficiency. When drying unbound water, the thermal efficiency can reach more than 70%.

4. Compared with ordinary dryers on the market, this clay dryer has a high output, which is more than twice that of ordinary dryers;

5. There are no requirements for the working environment, and clay can be dried in harsh environments without affecting the drying effect and efficiency;

6. Made of high wear-resistant materials, it has strong wear resistance and pressure resistance, and has a longer service life;

7. The quality is excellent, the operation is smooth, the number of failures is very few, and the overall operating cost is reduced.

Working Principle

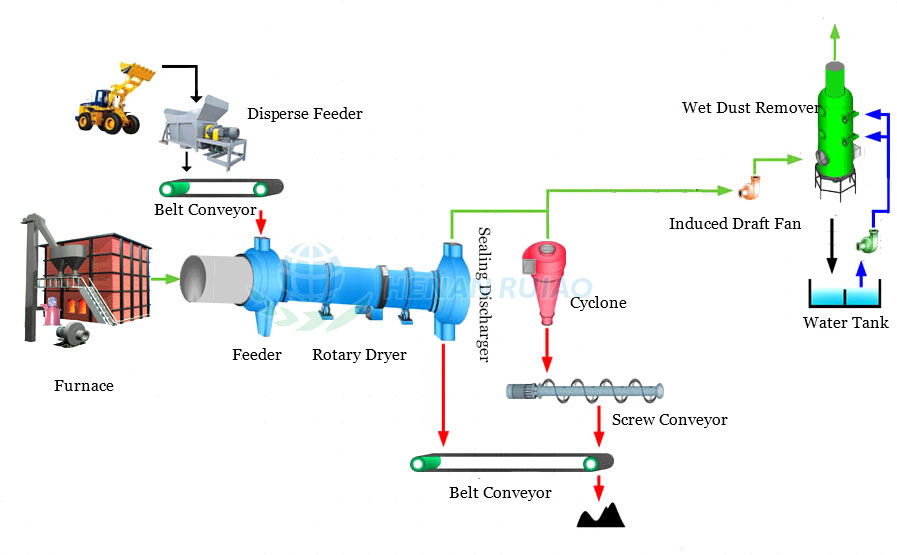

The wet materials are sent to the hopper by a belt conveyor or bucket elevator, and then enter the feeding end through the feeding tube of the hopper feeder. The inclination angle of the feeding pipe should be greater than the natural inclination angle of materials to facilitate the smooth flow of materials into the dryer. The drying cylinder is a rotating cylinder, which is slightly inclined with the horizontal line. The material is added from the higher end, and at the same time, the hot air contacts the material in the downstream direction, resulting in sufficient heat exchange. When the cylinder rotates, the material moves to the lower end under the action of the lifting plate and its own gravity. When the wet material advances in the cylinder, it continuously exchanges heat with the hot air or the cylinder, thereby drying the wet material. Then, the finished product is sent out from the discharge end through a belt conveyor or screw conveyor.

Technical Parameters

Model | Drum diameter | Drum | Capacity | Rotary Speed | Drum Inclination | Power | Weight |

Φ1.0×10 | Φ1000 | 10000 | 1-4 | 1.1-6 | 5 | 7.5 | 7.85 |

Φ1.2×12 | Φ1200 | 12000 | 3-7 | 1.2-6.5 | 5 | 11 | 13.3 |

Φ1.5×14 | Φ1500 | 14000 | 7-10 | 1.4-7 | 5 | 15 | 17.9 |

Φ1.6×14 | Φ1600 | 14000 | 8-11 | 1.4-7 | 5 | 15 | 18.6 |

Φ1.8×14 | Φ1800 | 14000 | 9-13 | 3.5-6.5 | 5 | 15 | 20.85 |

Φ2.4×18 | Φ2400 | 18000 | 21-31 | 2.2-7.4 | 4 | 30 | 45 |

Φ2.4×22 | Φ2400 | 22000 | 26-38 | 2.2-7.4 | 4 | 37 | 58 |

Φ2.6×20 | Φ2600 | 20000 | 28-40 | 2.2-7.4 | 4 | 45 | 60.5 |

Φ3.0×25 | Φ3000 | 25000 | 46-64 | 8.4-3.85 | 4 | 75 | 96 |

Φ3.2×25 | Φ3200 | 25000 | 60-80 | 2.4-7.6 | 4 | 90 | 119 |

Send a Message

Get In Touch!

Address

No.11 Changchun Road, High-Tech Development Zone, Zhengzhou, Henan, China

- 19900970386