Bentonite Dryer

Introduction

Rotary dryer are usually chosen to dry bentonite. Based on the characteristics of bentonite, our company has made effective technical improvements to the rotary dryer on how to improve the material filling rate and extend the residence time of the material in the drum. It adopts a new combined lifting device to to increase the contact area between bentonite and hot air, so that the bentonite can fully exchange heat and dehydrate; so to improve heat utilization and increase output.

Besides, our bentonite dryer featured in continuous production, fast drying speed and simple operation.

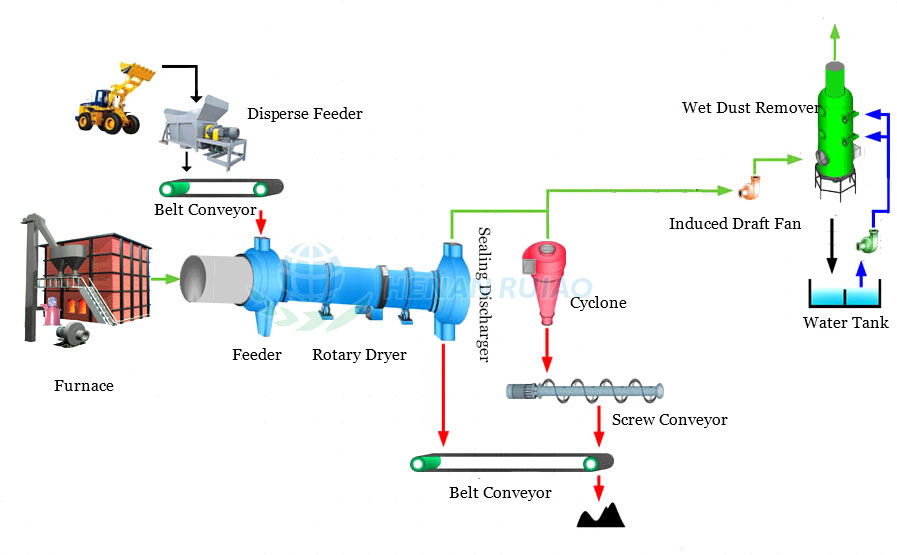

Bentonite Dryer Working Principle

The bentonite to be dried enters the drum from the feeder and the inlet and is pushed forward by the lifting plate. Since the dryer is placed at an angle, the bentonite flows to the rear end under the action of gravity and rotation. On the other hand, the bentonite is repeatedly picked up by the lifting board, brought to the upper end, and then continuously spread down. The bentonite forms a uniform curtain inner the dryer and fully exchanges heat with the hot air flow. As the bentonite is repeatedly spread, the moisture contained in it is gradually dried, thereby achieving the purpose of rapid drying.

Why Choose Our Bentonite Dryer

1. High-efficiency and energy saving

Efficient heat conduction and heat convection, achieve rapid drying of bentonite, and at the same time have low energy consumption, helping to save energy costs.

2. Uniform drying

The rotating design of the drum causes the raw material to continuously tumble in the drum, ensuring that the bentonite is heated evenly and achieving uniform drying.

3. Easy to operate

simple to operate and easy to control and maintain. The operator can adjust the rotation speed of the drum and the temperature of the hot air according to production needs to achieve the best drying effect.

4. Various heating choices

Depending on users’ situation, the heating source can be coal, gas, diesel oil, biomass pellet, etc.

5. Environmental friendly

Multiple advanced dust removal are adopted to ensure that emissions of exhaust gas meet local environmental protection standards.

Technical Parameters

Model | Drum diameter | Drum | Capacity | Rotary Speed | Final Moisture | Power | Weight |

Φ1.0×10 | Φ1000 | 10000 | 1-4 | 1.1-6 | ≤5 | 7.5 | 7.85 |

Φ1.2×12 | Φ1200 | 12000 | 3-7 | 1.2-6.5 | ≤5 | 11 | 13.3 |

Φ1.5×14 | Φ1500 | 14000 | 7-10 | 1.4-7 | ≤5 | 15 | 17.9 |

Φ1.6×14 | Φ1600 | 14000 | 8-11 | 1.4-7 | ≤5 | 15 | 18.6 |

Φ1.8×14 | Φ1800 | 14000 | 9-13 | 3.5-6.5 | ≤5 | 15 | 20.85 |

Φ2.4×18 | Φ2400 | 18000 | 21-31 | 2.2-7.4 | ≤5 | 30 | 45 |

Φ2.4×22 | Φ2400 | 22000 | 26-38 | 2.2-7.4 | ≤5 | 37 | 58 |

Φ2.6×20 | Φ2600 | 20000 | 28-40 | 2.2-7.4 | ≤5 | 45 | 60.5 |

Φ3.0×25 | Φ3000 | 25000 | 46-64 | 8.4-3.85 | ≤5 | 75 | 96 |

Φ3.2×25 | Φ3200 | 25000 | 60-80 | 2.4-7.6 | ≤5 | 90 | 119 |

Send a Message

Get In Touch!

Address

No.11 Changchun Road, High-Tech Development Zone, Zhengzhou, Henan, China

- 19900970386