Alfalfa Dryer

What's alfalfa dryer?

The three-layer single-channel rotary dryer is generally used for drying alfalfa grass. This alfalfa grass dryer features high output, high efficiency, energy saving, and has a small footprint. When used in conjunction with a clean hot air furnace, it is particularly suitable for drying high-moisture materials like grass, quickly reducing the moisture content of grass from 65-75% to 14-18%. The dryer achieves energy savings of 30-50%, allowing for reduced energy consumption. This alfalfa grass dryer is also suitable for drying materials with a moisture content of 45-75%, such as alfalfa, wheat straw, barley straw, oat straw, rye straw, straw, sorghum straw, corn straw, tuber vines, and legume stems. The company optimizes the drying process technology and equipment selection configuration based on the characteristics of each material, production capacity, quality requirements, application needs, cost control, automation level, and on-site working conditions.

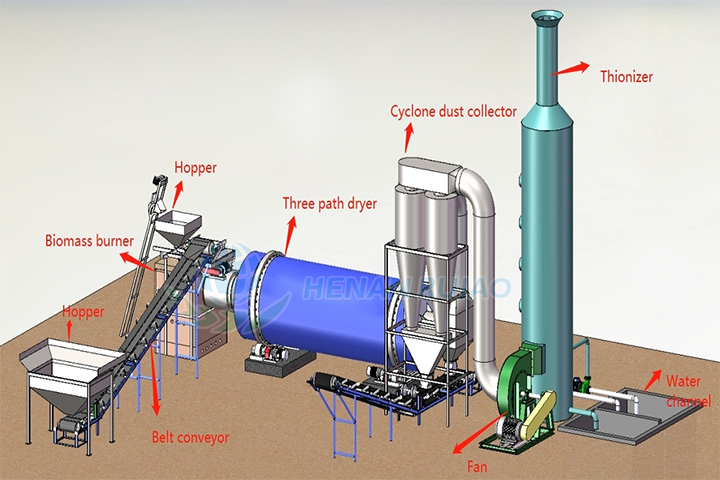

Alfalfa Dryer Working Process

The alfalfa grass with the moisture content of about 45-75% is sent into the drum dryer by a conveyor for concurrent drying. The alfalfa grass is continuously lifted and scattered under the inner layer of the lifting plates, moving forward in a spiral manner. Through the inner, middle, and outer layers, heat exchange occurs between the alfalfa grass and hot air, achieving the drying effect. Dried alfalfa grass is quickly discharged from the drum under the action of airflow, while wet alfalfa grass that has not reached the drying effect cannot move quickly due to its own weight. The alfalfa grass is fully dried during the process, reducing its moisture content to 14-18% (as required by the customer), and is discharged by a screw conveyor.

Alfalfa Dryer Advantages

1. Fast drying speed and large output

Adopting three-drum drying technology with special lifting plate inside, the material is fully in contact with the hot air, resulting in high heat transfer coefficient.

2. High thermal efficiency and low drying cost

Energy saving 15% to 20% compared to conventional drying equipment.

3. Good drying quality

Adopting new high-temperature and rapid drying process, the feeding system operates uniformly, and the temperature adjustment system is automatically controlled. Therefore, the dried alfalfa has a bright green color, with a protein content 5-7% higher than that of naturally dried hay.

4. Production safety and good working environment

Due to the fully sealed operation of the entire system and the implementation of negative pressure operation, the production environment is good.

5. Multiple uses, moderately priced

The drying system has the same good drying effect on other economic crops such as ginkgo leaves, straw plants, vegetables, Chinese herbal medicine, sawdust, fruit residue, etc.

Technical Parameters

Model | RASG2010-3 | RASG2209-3 | RASG2609-3 | RASG3009-3 |

Capacity | 1-2t/h | 1-2t/h | 2-3t/h | 4-6t/h |

Input moisture | 35-60% | |||

Output moisture | 12-15% | |||

Drying temperature | 450℃ | |||

Floor space | 10m×20m | 10m×20m | 15m×30m | 15m×40m |

Send a Message

Get In Touch!

Address

No.11 Changchun Road, High-Tech Development Zone, Zhengzhou, Henan, China

- 19900970386