Secadora de bagazo

Introducción

El procesamiento de la caña de azúcar y la fabricación de azúcar en los ingenios producirán una gran cantidad de bagazo de caña de azúcar. El bagazo de caña de azúcar se puede secar para producir combustibles de biomasa, alimento para animales, etc. Y se puede utilizar como sustituto de la madera para la producción de pulpa, papel y cartón para mejorar el valor de utilización del bagazo de caña de azúcar.

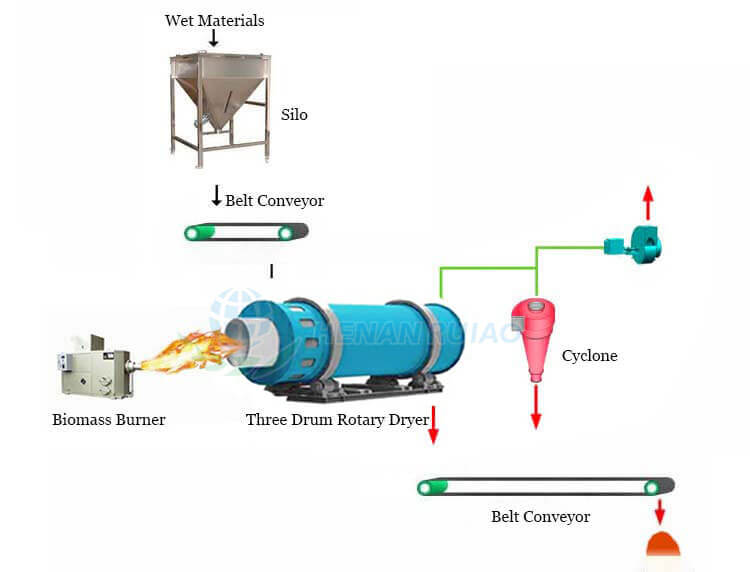

Principio de funcionamiento

Después de que el bagazo húmedo ingresa a la secadora, se dispersa uniformemente y entra en contacto total con el aire caliente al voltear las tablas distribuidas uniformemente en el tambor, formando una cortina para acelerar el calor de secado y la transferencia de masa. El bagazo se descarga desde otra válvula de descarga del secador bajo la acción de tableros inclinados y medios térmicos.

Ventajas

1. El cilindro de tres canales del secador de bagazo tiene un buen efecto de autocalentamiento, lo que reduce en gran medida la pérdida de calor; la eficiencia térmica puede alcanzar el 80%.

2. Su espacio es más pequeño que el del secador tradicional, reduce el área de la planta y ahorra aproximadamente el 40% de la inversión del proyecto. 50% de ahorro en el consumo de energía;

3. El sistema de secado de bagazo adopta un control completamente automático, que es simple y conveniente de operar, puede funcionar continuamente durante 24 horas y tiene una larga vida útil;

4. El secador de bagazo se puede utilizar con el sistema de secado de bagazo en muchas industrias, como la de combustible de pellets de biomasa, la quema de centrales eléctricas de bagazo, la industria de paneles a base de madera, etc.

5. El secador de bagazo puede utilizar varias fuentes de calor, como estufas de aire caliente accionadas manualmente, calderas de gasóleo en centrales eléctricas grandes, estufas de aire caliente directas o indirectas, gas, fueloil, estufas de carbón, etc. Es conveniente para que los usuarios elijan según su situación real.

Parámetros técnicos

Modelo | RASG2010-3 | RASG2209-3 | RASG2609-3 | RASG3009-3 |

Capacidad | 1-2t/h | 1-2t/h | 2-3t/h | 4-6t/h |

Humedad de entrada | 35-60% | |||

Humedad de salida | 12-15% | |||

Temperatura de secado | 450℃ | |||

Espacio de piso | 10m×20m | 10m×20m | 15m×30m | 15m×40m |

Enviar un mensaje

¡Ponerse en contacto!

DIRECCIÓN

No.11 Changchun Road, Zona de Desarrollo de Alta Tecnología, Zhengzhou, Henan, China

- 19900970386