Three Pass Rotary Drum Dryer

Introduction

The three pass rotary drum dryer is special designed on the basis of single drum drying equipment. It can reduce drying energy consumption and expand production capacity. After the improvement of our technicians, the applicability of three layer rotary drum dryer is further enhanced, and the drying effect of high humidity materials is excellent.

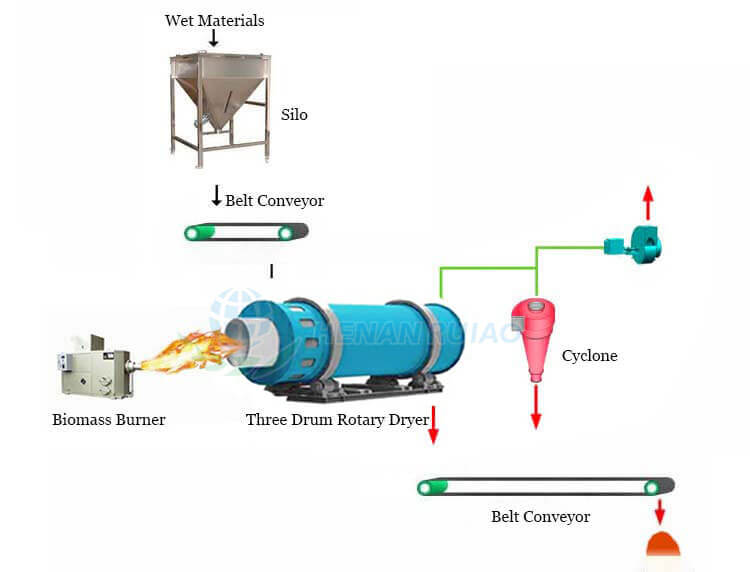

Working Principle

After the wet material enter the dryer, it is evenly dispersed and fully in contact with hot air under the flipping of evenly distributed boards in the drum, forming a curtain to accelerate drying heat and mass transfer. The material is discharged from another discharge valve of the dryer under the action of inclined boards and thermal media.

Advantages

1. The self heating effect is good, greatly reducing heat loss, and the thermal efficiency can reach 80%.

2. The floor space is smaller than traditional dryer, saving project investment by about 40%, and saving 50% power consumption.

3. Adopting fully automatic control, the operation is simple and convenient, can run continuously for 24 hours, and has a long service life.

4. The three drum dryer can be used in many industries, such as biomass pellet fuel, bagasse power plant combustion, artificial board industry, etc.

5. Various heat sources can be select, such as hand-fired hot air stove, oil-fired boiler in large power plant, direct or indirect hot air stove, gas, fuel oil, coal-fired stove, etc.

Technical Parameters

Model | RASG2010-3 | RASG2209-3 | RASG2609-3 | RASG3009-3 |

Capacity | 1-2t/h | 1-2t/h | 2-3t/h | 4-6t/h |

Input moisture | 35-60% | |||

Output moisture | 12-15% | |||

Drying temperature | 450℃ | |||

Floor space | 10m×20m | 10m×20m | 15m×30m | 15m×40m |

Send a Message

Get In Touch!

Address

No.11 Changchun Road, High-Tech Development Zone, Zhengzhou, Henan, China

- 19900970386