Limestone Dryer

Introduction

When it comes to drying limestone, normally rotary drum dryer will be chosen. Rotary dryer is usually consists of rollers, transmission devices, support devices and sealing rings. Its working principle is to place the limestone inside the drum and then drum rotates driven by transmission device, which causes the limestone to continuously tumble in the drum, and then heat the limestone through hot air or other heat sources to evaporate the water and achieve the uniform drying of limestone. And the final moisture content of the dried limestone can be less than 5%

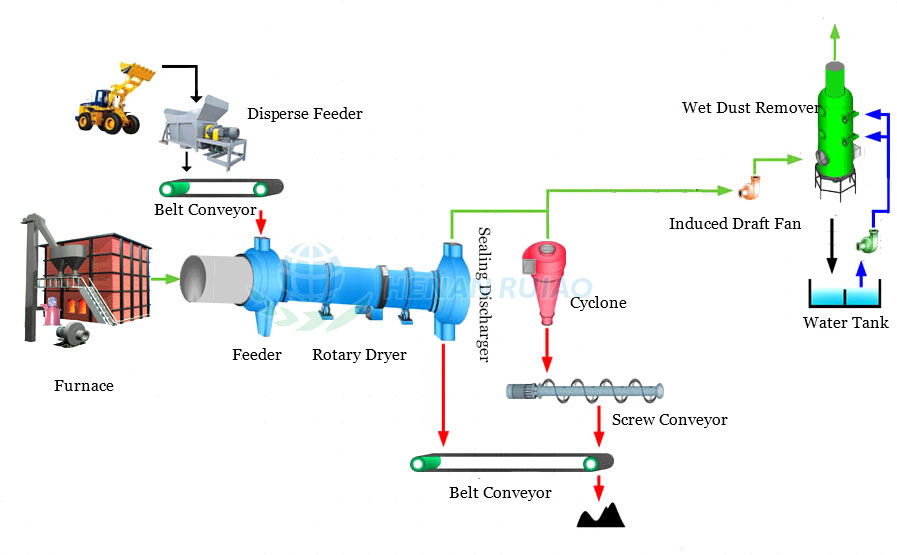

Limestone Rotary Dryer System

Limestone Rotary Dryer Structure

1. Rotary Drum

It is the main part where limestone is placed and dried. The drum is usually a long, cylindrical container made of high temperature and abrasion resistant material to withstand the rotation and drying process of the limestone.

2. Transmission device

used to drive the rotation of the drum, usually composed of a motor, reducer, etc. The transmission is designed to provide sufficient torque and a stable rotational speed to ensure that the limestone is evenly heated within the drum.

3. Support device

The structure that supports and stabilizes the drum to ensure its normal operation. The support device usually includes the bearings, bearing seats and other parts of the drum.

4. Feeding device

The part where the limestone to be treated is introduced into the drum. The design of the feeding device should ensure that the limestone can be evenly distributed in the drum to improve the drying effect.

5. Discharge device

Take out the part of dried limestone from the drum. The design of the discharging device should facilitate the smooth discharge of limestone.

6. Hot air stove

Provides hot air or other heat sources, and introduces hot air into the drum through the air inlet. The heating effect of hot air evaporates the water in the limestone, completing the drying process.

7. Sealing device

To prevent the leakage of hot air and moisture, sealing rings and other devices are usually used to improve drying efficiency and protect the environment.

Limestone Dryer Advantages

The advantages of this type of dryer include ease of operation, low energy consumption, high thermal efficiency and better protection of limestone materials. The design inside the drum often helps ensure that the limestone is heated evenly, improving drying results. The use of sealing rings can reduce energy waste and ensure full utilization of hot air.

Overall, limestone drum dryers play an important role in the limestone material handeling industry, improving production efficiency and ensuring product quality.

Technical Parameters

Model | Drum diameter | Drum | Capacity | Final Moisture (%) | Drum Inclination | Power | Weight |

Φ1.0×10 | Φ1000 | 10000 | 1-4 | ≤5% | 5 | 7.5 | 7.85 |

Φ1.2×12 | Φ1200 | 12000 | 3-7 | ≤5% | 5 | 11 | 13.3 |

Φ1.5×14 | Φ1500 | 14000 | 7-10 | ≤5% | 5 | 15 | 17.9 |

Φ1.6×14 | Φ1600 | 14000 | 8-11 | ≤5% | 5 | 15 | 18.6 |

Φ1.8×14 | Φ1800 | 14000 | 9-13 | ≤5% | 5 | 15 | 20.85 |

Φ2.4×18 | Φ2400 | 18000 | 21-31 | ≤5% | 4 | 30 | 45 |

Φ2.4×22 | Φ2400 | 22000 | 26-38 | ≤5% | 4 | 37 | 58 |

Φ2.6×20 | Φ2600 | 20000 | 28-40 | ≤5% | 4 | 45 | 60.5 |

Φ3.0×25 | Φ3000 | 25000 | 46-64 | ≤5% | 4 | 75 | 96 |

Φ3.2×25 | Φ3200 | 25000 | 60-80 | ≤5% | 4 | 90 | 119 |

Send a Message

Get In Touch!

Address

No.11 Changchun Road, High-Tech Development Zone, Zhengzhou, Henan, China

- 19900970386