Kaolin Dryer

Kaolin Rotary Dryer Introduction

The rotary dryer is often chose for drying kaolin for its large processing capacity, low fuel consumption and low drying cost, etc. Our kaolin dryer is designed based on the rotary dryer and combined with the characteristics of kaolin materials.

And kaolin rotary dryer has the characteristics of high temperature resistance so that it can use high temperature hot air to dry the raw materials quickly. The kaolin rotary dryer can be used for drying of kinds of kaolin, kaolin powder, clay, coal, mining, bauxite, bentonite, aluminum slag, metal slag, etc. The final moisture content of the dried material can be less than 5%.

Kaolin Rotary Dryer Working Principle

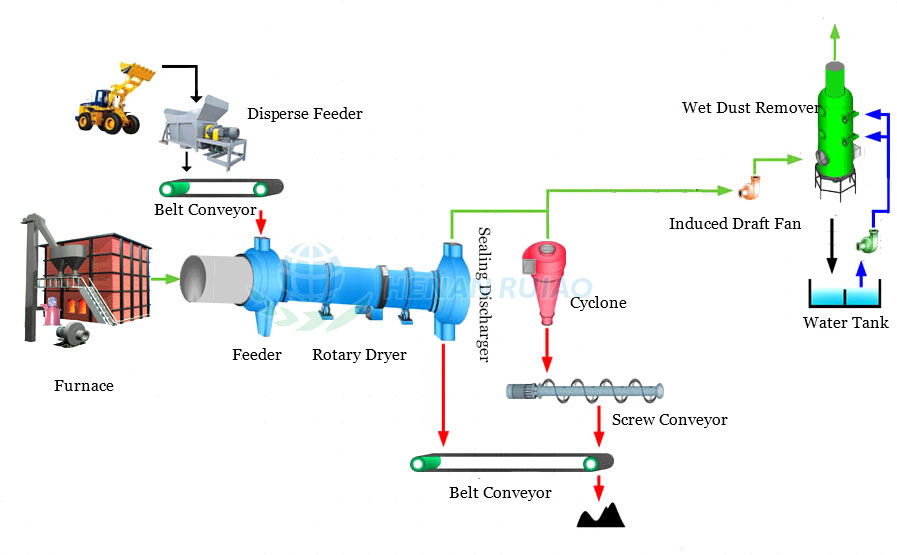

After the wet materials are fed into the dryer by the feeding system, the materials are evenly distributed and dispersed in the dryer under the action of the evenly distributed lifting plates inner the drum, and are fully contacted with the co-current (counter-current) hot air, which accelerates the heat transfer. During the drying process, the material moves in a controlled manner under the action of the inclined lifting plate and hot air flow, and the dried material is discharged from the other end of the dryer.

Why Choose Our Kaolin Rotary Dryer

1.Large processing capacity and low drying cost

The kaolin rotary dryer has the advantage of strong anti-overload ability, large processing capacity, low fuel consumption, and low drying cost.

2. High thermal efficiency

Using the downstream drying method, high-temperature flue gas and wet materials enter the dryer from the same side; high-temperature flue gas is used to obtain high evaporation intensity; and the dryer outlet temperature is low, so the thermal efficiency is high;

3. Adjustable parameters

The operating parameters can be changed according to the features of different materials, so that the materials can form a stable full-section curtain in the dryer drum, and the heat exchange is more sufficient;

4.Unique inner structure

The new internal structure enhances the cleaning and heat conduction of dispersed materials, eliminates the sticking phenomenon on the inner wall of the drum, and has a wider adaptability to the moisture and viscosity of materials;

5. Uniform and continuous drying without blockage

The new feeding and discharging device eliminates the phenomena of feeding blockage, discontinuity, unevenness and return of the dryer system, ensuring the drying quality while reducing the load of the dust removal system;

6. Guaranteed quality of the dried material and processing capacity

The design of the dryer system takes into account the production margin. While ensuring the material drying requirements, there is no need to change the dryer even if the output increases slightly;

7. Particle size and moisture of the died material can be adjusted

Particle size and moisture of the dried kaolin can be controlled according to user requirements. When kaolin is dried, the product moisture can reach less than 5%, and the particle size can be controlled below 8mm.

Technical Parameters

Model(mm) | Inclination (%) | Rotating speed(r/min) | Inlet Air Temperature(℃) | Power(kw) | Capacity(t/h) | Weight(t) |

Ф1200×10000 | 3-5 | 3-8 | ≤700 | 7.5 | 1.8-5 | 14.5 |

Ф1800×12000 | 3-5 | 2-6 | ≤800 | 18 | 5-12 | 25 |

Ф2200×18000 | 3-5 | 1.5-6 | ≤800 | 22 | 10-18 | 53.8 |

Ф2200×20000 | 3-5 | 1.5-6 | ≤800 | 30 | 12-20 | 56 |

Ф3000×20000 | 3-5 | 1.5-5 | ≤800 | 55 | 25-35 | 78 |

Ф3000×25000 | 3-5 | 1.5-5 | ≤800 | 75 | 32-40 | 104.9 |

Send a Message

Get In Touch!

Address

No.11 Changchun Road, High-Tech Development Zone, Zhengzhou, Henan, China

- 19900970386