Mineral Dryer

Mineral Rotary Dryer Introduction

The mineral rotary drum dryer is used for drying mining materials such as limestone, coal , slag, ore, phosphate, kaolin, clay and other materials. The internal structure of the drum dryer is designed according to the material characteristics; It has the advantages of reasonable structure, uniform drying, high output, low energy consumption and convenient operation. The final moisture content of the dried material can be less then 5% and can be adjustable according to your needs.

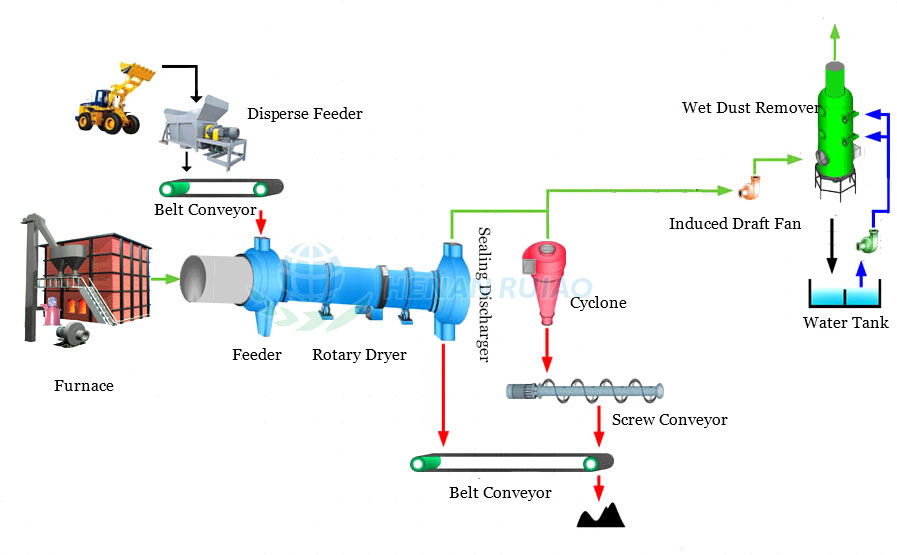

Mineral Dryer System

The mineral rotary drum dryer system mainly consists of heat source device, rotary dryer, dust removing device, induced draft fan, supporting roller device, feeding and discharging device and other parts.

After the wet materials are fed to the dryer, the materials are evenly distributed and dispersed in the dryer under the action of the evenly distributed lifting plates inner the drum, and are fully contacted with the co-current (counter-current) hot air, which accelerates the heat transfer. During the drying process, the material moves in a controlled manner under the action of the inclined lifting plate and hot air flow, and the dried material is discharged from the other end of the dryer.

Application

Mineral rotary drum dryer is widely used in mining production and are mainly used for drying various ores, ore and other mining raw materials. The following are the main applications of mineral dryer:

1. Metal ore processing: iron ore, copper ore, aluminum ore, etc.

2. Non-metallic ore processing: gypsum, kaolin, clay, bentonite, expanded soil, vermiculite, etc.

3. Coal mine coal treatment: coal, lignite, raw coal, etc.

4. Chemical industry: fertilizer raw materials, chemical products, etc.

5. Environmental protection projects: ore slag, ore sludge, etc.

Advantages

1. High-efficiency

Efficient heat conduction and heat convection, achieve rapid drying of minerals, and at the same time have low energy consumption, helping to save energy costs.

2. Reliable and stable

The equipment has a stable structure and long service life, and can work continuously and stably, reducing production interruptions caused by equipment failure.

3. Easy to operate

simple to operate and easy to control and maintain. The operator can adjust the rotation speed of the drum and the temperature of the hot air according to production needs to achieve the best drying effect.

4. Uniform drying

The rotating design of the drum causes the raw material to continuously tumble in the drum, ensuring that the minerals is heated evenly and achieving uniform drying.

5. High-quality dried product

Uniform heating during the drying process helps maintain the original properties of the minerals, improves the quality of the final product, and reduces the loss rate in production.

Technical Parameters

| Model | Capacity(T/D) | Input Moisture(%) | Output Moisture(%) | Power(kw) | Floor Space(㎡) |

| RAMG1918 | 300±10 | 25±5 | ≤5 | 109 | 7m×25m |

| RAMG2218 | 500±10 | 25±5 | ≤5 | 128 | 8m×30m |

| RAMG2520 | 700±12 | 25±5 | ≤5 | 240 | 8m×30m |

| RAMG2822 | 1000±15 | 25±5 | ≤5 | 400 | 8m×40m |

| RAMG3024 | 1200±20 | 25±5 | ≤5 | 480 | 12m×50m |

| RAMG3428 | 1500±30 | 25±5 | ≤5 | 600 | 12m×60m |

| RAMG3830 | 1800±30 | 25±5 | ≤5 | 800 | 16m×70m |

| RAMG4032 | 2000±30 | 25±5 | ≤5 | 1000 | 18m×70m |

| RAMG4238 | 2500±30 | 25±5 | ≤5 | 1200 | 20m×80m |

Send a Message

Get In Touch!

Address

No.11 Changchun Road, High-Tech Development Zone, Zhengzhou, Henan, China

- 19900970386