Raw Coal Dryer

Introduction

Raw coal refers to coal blocks that have only undergone simple screening. This type of coal block has a relatively high ash content and moisture content. The raw coal dryer adopts downstream drying technology, which fully exchanges heat to achieve rapid drying of raw coal. Different dust removal kits can also be selected according to the different environmental requirements of customers, reducing the temperature and dust emissions of exhaust gas, thereby achieving the goals of green environmental protection and energy conservation and emission reduction.

Working Principle

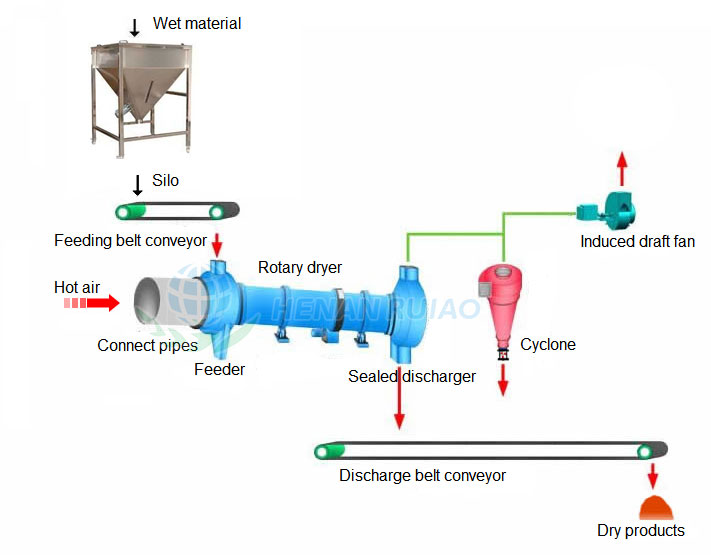

The Ruiao raw coal drying system mainly consists of a heat source, dispersed feeding, belt feeding machine, drum equipment, unloader, dust removal equipment, belt discharge machine, induced draft fan, and power distribution operation.

The materials are shoveled into the pulverizing feeder by the loader, then transferred to the feeding belt conveyor by the raw coal pulverizing feeder. They are then fed into the drum spiral propulsion device by the feeding belt conveyor, and then quickly guided to the inclined lifting area by the large angle guide plate. With the rotation of the drum and the inclination of the cylinder, they are lifted from the bottom of the cylinder and dropped from the top of the cylinder, forming a “material curtain”, The high-temperature flue gas entering the drying drum at the same end as the wet material passes through it, causing the wet material to form conduction and convective heat exchange, preheating the wet material and evaporating some moisture.

Features

1. Continuous Operation:

The design of the rotary drum allows for a continuous and seamless drying process, ensuring a steady output of dried raw coal. This is essential for maintaining consistent production in coal preparation plants.

2. Uniform Drying

The rotating drum exposes the raw coal to a consistent and evenly distributed heat, promoting uniform drying throughout the material. This prevents uneven moisture content and clumping, resulting in a high-quality, homogeneous dried raw coal product.

3. Versatility:

Rotary drum raw coal dryers are adaptable to various types of raw coal, including different grades and moisture levels. This versatility makes them suitable for diverse applications within the coal processing industry.

4. Robust Construction:

Typically constructed with durable materials, these dryers are designed to withstand the abrasive nature of raw coal. The robust construction ensures a longer operational life and minimal maintenance requirements.

Workflow

Technical Parameters

| Model | Capacity(T/D) | Input Moisture(%) | Output Moisture(%) | Power(kw) | Floor Space(㎡) |

| RAMG1918 | 300±10 | 25±5 | 13±2 | 109 | 7m×25m |

| RAMG2218 | 500±10 | 25±5 | 13±2 | 128 | 8m×30m |

| RAMG2520 | 700±12 | 25±5 | 13±2 | 240 | 8m×30m |

| RAMG2822 | 1000±15 | 25±5 | 13±2 | 400 | 8m×40m |

| RAMG3024 | 1200±20 | 25±5 | 13±2 | 480 | 12m×50m |

| RAMG3428 | 1500±30 | 25±5 | 13±2 | 600 | 12m×60m |

| RAMG3830 | 1800±30 | 25±5 | 13±2 | 800 | 16m×70m |

| RAMG4032 | 2000±30 | 25±5 | 13±2 | 1000 | 18m×70m |

| RAMG4238 | 2500±30 | 25±5 | 13±2 | 1200 | 20m×80m |

Send a Message

Get In Touch!

Address

No.11 Changchun Road, High-Tech Development Zone, Zhengzhou, Henan, China

- 19900970386