Coal Dryer

Introduction

The coal dryer is suitable for drying and processing different types of coal such as raw coal, blue coal, brown coal, and clean coal. The drying temperature, pressure, air volume, and speed of the dryer are strictly controlled according to the characteristics of different kinds of coal, and use different forms of lifting devices, cleaning devices, and crushing devices inside the drum to solve the sticking problem during drying process.

According to the different needs of customers, our products have formed a large-scale and serialized drying system, with more than 30 series of products and different internal structures of dryers to ensure drying effects. The diameter of the drying equipment ranges from Φ1.9 to Φ4.5 meters, the length ranges from 16 meters to 30 meters, and the daily processing capacity ranges from 200 to 2,000 tons. The feed moisture content is 40±5%, and the drying moisture content can be reduced to 10±2%. , or even lower.

Working Principle

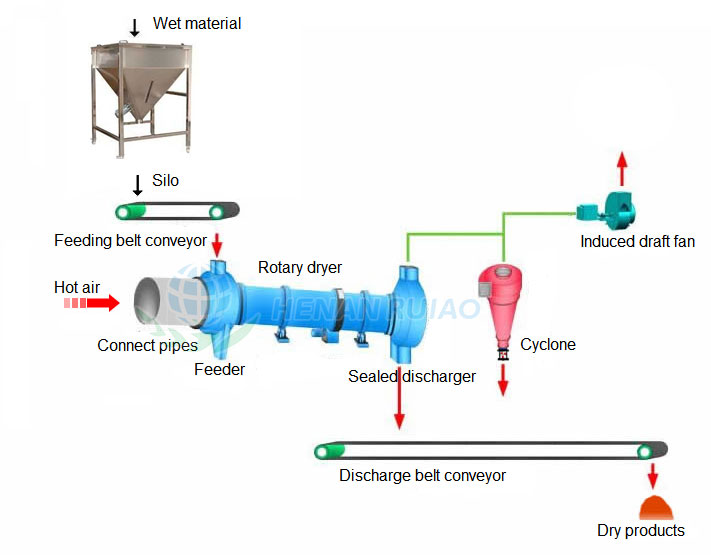

The coal dryer system is composed of heating equipment, feeders, conveyors, drum dryers, dust collectors, distribution cabinets, and other supporting equipment, which cooperate with each other to complete the entire drying process. Its working principle: Wet materials are transported to the drum dryer through feeders and conveyors. The materials roll continuously with the drum, and under the unique device inside the drum, the contact area with high-temperature hot air is increased, greatly reducing the moisture content of the materials. After drying, the materials are discharged from the discharge port, completing the precipitation drying of the entire high humidity material.

Features

1. Flexible and diverse combustion equipment, furnace body and furnace type design, pursuing efficient and energy-saving heat source utilization schemes.

2. Fiberglass and stainless steel materials are used in dust removal systems to solve dust removal technical problems such as wear and corrosion.

3. The successful application of bag filter has opened up new ideas for high-temperature and high humidity tail gas dust removal.

4. Equipped with advanced, reliable and practical power supply and distribution and control systems, greatly improving the automation level of the system.

Technical Parameters

| Model | Capacity(T/D) | Input Moisture(%) | Output Moisture(%) | Power(kw) | Floor Space(㎡) |

| RAMG1918 | 300±10 | 25±5 | 13±2 | 109 | 7m×25m |

| RAMG2218 | 500±10 | 25±5 | 13±2 | 128 | 8m×30m |

| RAMG2520 | 700±12 | 25±5 | 13±2 | 240 | 8m×30m |

| RAMG2822 | 1000±15 | 25±5 | 13±2 | 400 | 8m×40m |

| RAMG3024 | 1200±20 | 25±5 | 13±2 | 480 | 12m×50m |

| RAMG3428 | 1500±30 | 25±5 | 13±2 | 600 | 12m×60m |

| RAMG3830 | 1800±30 | 25±5 | 13±2 | 800 | 16m×70m |

| RAMG4032 | 2000±30 | 25±5 | 13±2 | 1000 | 18m×70m |

| RAMG4238 | 2500±30 | 25±5 | 13±2 | 1200 | 20m×80m |

Send a Message

Get In Touch!

Address

No.11 Changchun Road, High-Tech Development Zone, Zhengzhou, Henan, China

- 19900970386