Cassava Residue Dryer

Introduction

Cassava residue can be used as livestock feed after drying. The cassava residues dryer can dehydrate various cassava dregs with moisture content of about 80% to less than 12%. The cassava residue dryer is equipped with special dehydration, temperature adjustment, lifting, guiding and dispersing devices, which effectively avoids sticking and blocking.

Advantages

1. High drying capacity

The material is dried through heat transfer, which reduces the moisture content of the material through full contact with high-temperature hot air. The equipment has good sealing performance and large drying output.

2. High cleanliness level

Clean heat sources can be chosen as fuel, and with corresponding dust removal equipment, the pollution caused by the equipment to the environment can be significantly reduced.

3. Reasonable structure, energy conservation and consumption reduction

Adopting three cylinder dryer, the inner part of the cylinder is equipped with special dispersing device and guiding material system, which can not only increase the daily drying output but also greatly reduce energy consumption.

4. Good drying quality

After drying with a dryer, the cassava residue is evenly dry and wet, with good product quality and increased economic value, creating higher economic benefits for users.

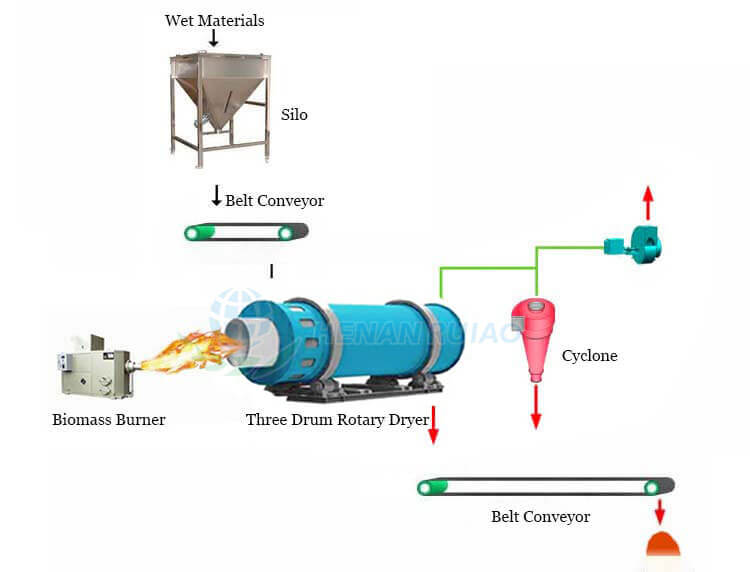

Composition

The Henan Ruiao cassava residue drying system mainly consists of heat source, belt feeding machine, drum dryer, discharge device, dust removal equipment, belt discharge machine, induced draft fan, and power distribution operation.

Working Principle

After pre dehydration by the dehydrator, the moisture content of the wet cassava residue is about 65%, which is transported to the feeding machine. The feeding machine then transports the cassava residue to the drying drum. The cassava residue is evenly dispersed and fully contacts with hot air under the flipping of the evenly distributed plate cutter in the drying drum, achieving the purpose of heat and mass transfer drying. After being dried by a cassava residue dryer, the cassava residue is discharged through a star shaped discharge device at the end of the drum, and the dry material is output by the discharge machine to complete the drying process.

Technical Parameters

Model | RASG2010-3 | RASG2209-3 | RASG2609-3 | RASG3009-3 |

Capacity | 1-2t/h | 1-2t/h | 2-3t/h | 4-6t/h |

Input moisture | 35-60% | |||

Output moisture | 12-15% | |||

Drying temperature | 450℃ | |||

Floor space | 10m×20m | 10m×20m | 15m×30m | 15m×40m |

Send a Message

Get In Touch!

Address

No.11 Changchun Road, High-Tech Development Zone, Zhengzhou, Henan, China

- 19900970386