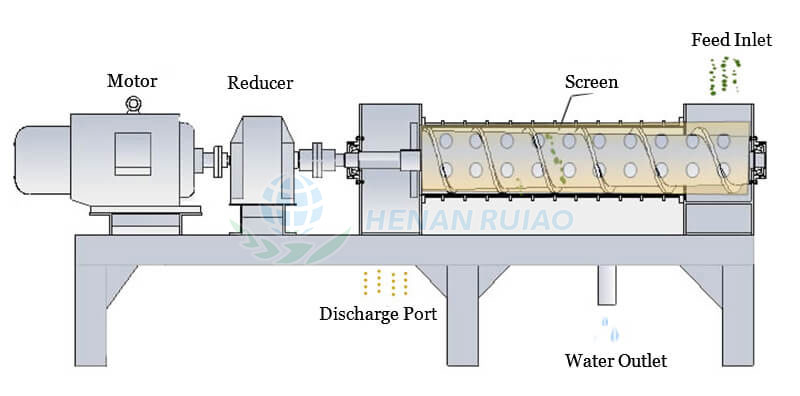

Screw Extrusion Dehydrator

Introduction

Screw extrusion dehydrator is designed to meet the needs of customers for dehydration of high humidity materials. It is suitable for the dehydration of materials such as distiller’s grains, fruit pomace, medicinal residues, cassava residues, and garbage. This dewatering machine can remove about 20% of the moisture in the materials, reducing the burden of drying equipment, and it is an indispensable processing equipment for high humidity materials before drying.

Working Principle

After the dewatering machine operates normally, the material is evenly added from the feeding box. The material after entering the machine is pushed forward along the axial direction by the spiral rotating blades. During the moving process, the material is subjected to a huge squeezing force due to the changing pitch and the action of the adjusting baffle, which causes the material to be mechanically dehydrated under the action of external force. Water is discharged through the sieve at the water outlet, and the dehydrated material is discharged from the discharge box.

Features

1. Low energy consumption, small floor space, physical and mechanical extrusion and dehydration.

2. There are two options: single-screw and double-screw series products.

3. Realize automatic control and reduced manual input.

Composition

The spiral extrusion dewatering machine is mainly composed of feed box, bearing seat, conical screw, water filter frame, water filter cage, machine base, coupling, motor, reducer, gearbox and other components.

Send a Message

Get In Touch!

Address

No.11 Changchun Road, High-Tech Development Zone, Zhengzhou, Henan, China

- 19900970386