Wood Chips Dryer

Introduction

The moisture content of wood chips is generally around 50%, and after drying, the moisture content is generally between 10-15%. The wood chips after drying can be used for carbon production, boiler combustion, gasification and power generation, etc. Our wood chip dryer is designed and manufactured specifically for drying various wood materials such as chips, veneer, sawdust, etc. It has the advantages of high thermal efficiency, light weight, wide applicability, and flexible temperature control.

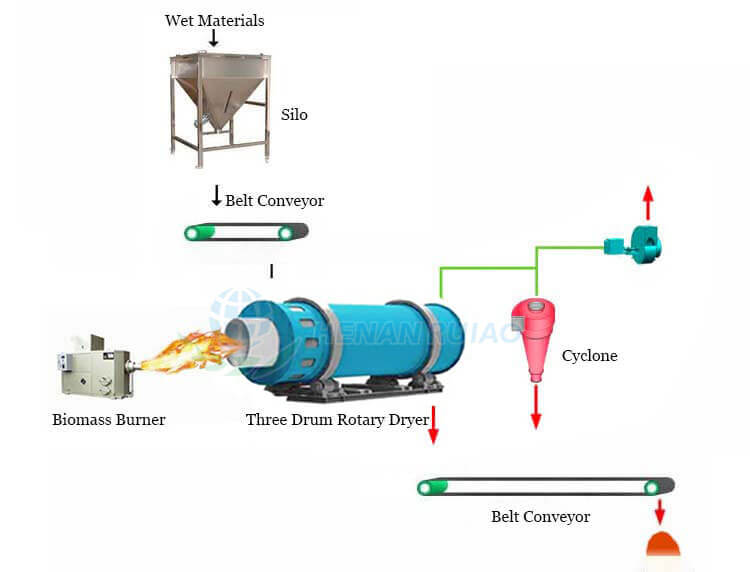

Working Principle

After the wet wood chips enter the dryer, they are evenly dispersed and fully in contact with hot air under the flipping of evenly distributed boards in the drum, forming a curtain to accelerate drying heat and mass transfer. The wood chip material is discharged from another discharge valve of the dryer under the action of inclined boards and thermal media.

Advantages

1. The thermal efficiency of the dryer cylinder’s self-insulation is as high as over 70%, while the thermal efficiency of traditional single-cylinder dryers is only 35%;

2. A variety of circumferential lifting material combinations are distributed to effectively control the drying time and achieve good drying effects;

3. Easily adjust the final moisture according to user requirements;

4. Equipped with a new energy-saving hot blast stove, it is highly energy-saving, thermally controllable, simple to operate, and reduces coal consumption by up to 60%.

Technical Parameters

Model | RASG2010-3 | RASG2209-3 | RASG2609-3 | RASG3009-3 |

Capacity | 1-2t/h | 1-2t/h | 2-3t/h | 4-6t/h |

Input moisture | 35-60% | |||

Output moisture | 12-15% | |||

Drying temperature | 450℃ | |||

Floor space | 10m×20m | 10m×20m | 15m×30m | 15m×40m |

Send a Message

Get In Touch!

Address

No.11 Changchun Road, High-Tech Development Zone, Zhengzhou, Henan, China

- 19900970386